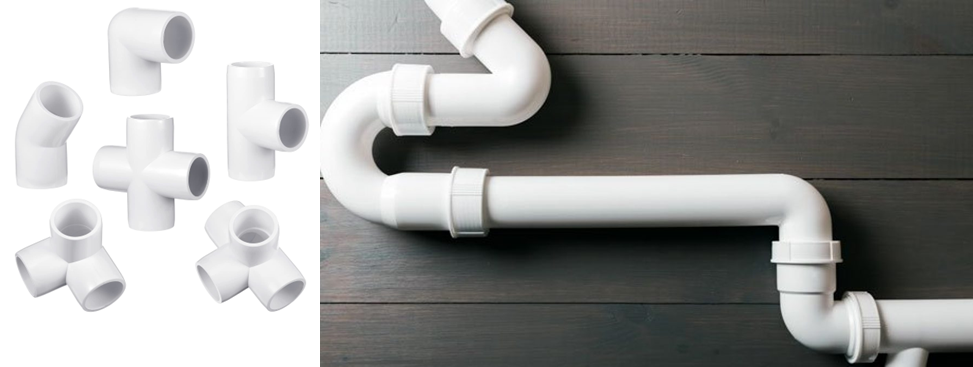

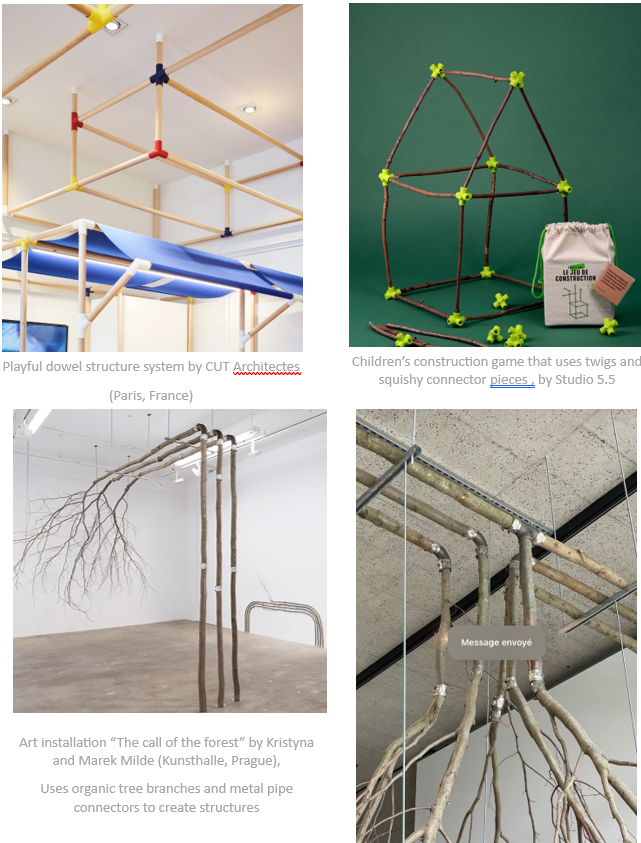

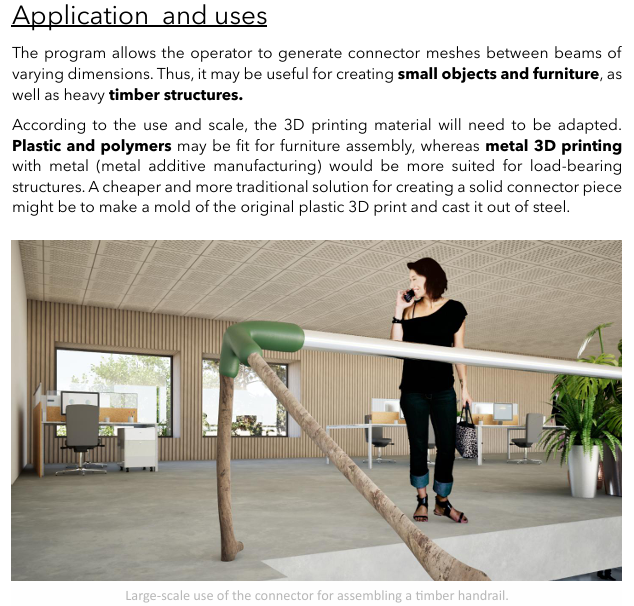

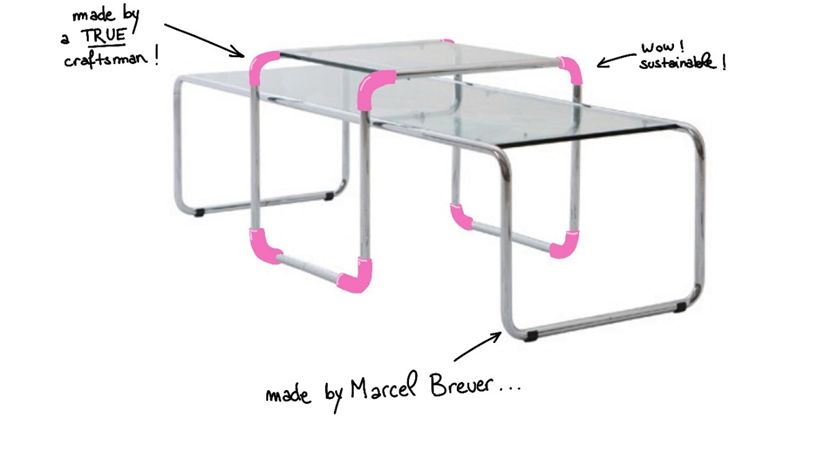

The aim of this project is to generate 3D printable connectors for assembling irregular shaped beams/branches. The project stems from the intention of reusing factory rejects and reclaimed construction materials which do not meet construction standards.

Standardization in Construction:

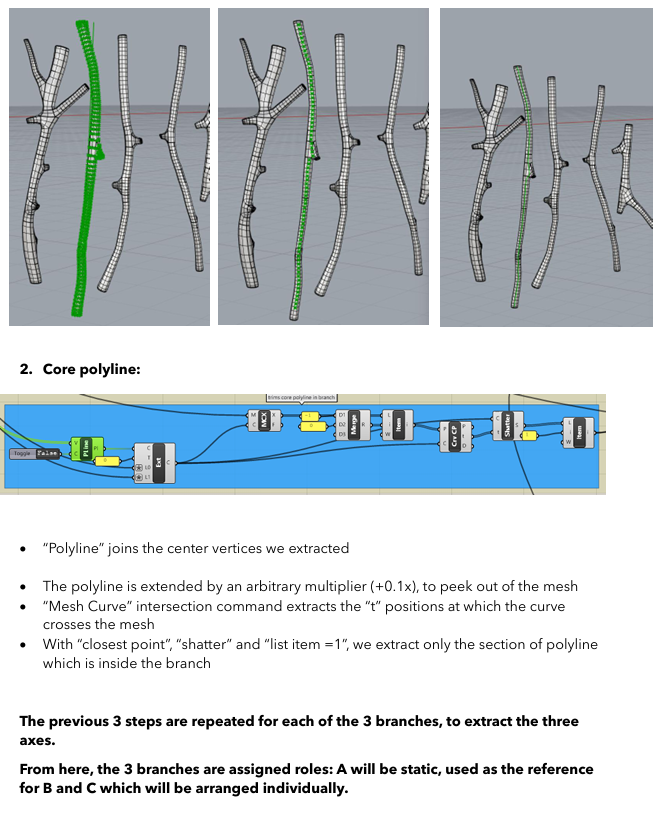

Over the last century, construction has increasingly relied on standardized elements—like lumber sizes, steel profiles, and panel dimensions—to improve efficiency, lower costs, and ensure compatibility across projects. This shift has streamlined manufacturing, logistics, and on-site work.

Factory Rejects:

A relative in lumber quality control noted that standardization leads to material waste. Beams with minor defects—even if structurally sound—are often rejected for not fitting machine lines or precise dimensions, not because they’re weak but because they don’t conform.

Reclaimed Materials:

Efforts to promote sustainability often highlight reclaimed wood, but these materials are frequently irregular in size or shape. Despite being strong, old timber is hard to integrate into modern systems or meet current codes, leading to it being underused.

Standardization and Sustainability:

While standardization speeds up construction, it also creates waste. Slightly flawed or non-standard components—like warped timber or odd-sized metal—are discarded even if usable. Rigid processes and automation leave little room for variation, reducing reuse and reinforcing a throwaway mindset. Efficiency comes at the cost of flexibility.

3D Printing as a Solution:

Seeing this waste issue, I began exploring ways to repurpose non-standard components. 3D printing, with its adaptability and efficiency in producing one-off forms, offers a promising method for integrating these atypical materials into new construction.

Connectors for non-standard beams

Deciding to focus mainly on pole shaped elements, I tried to find a way to connect them to one another.

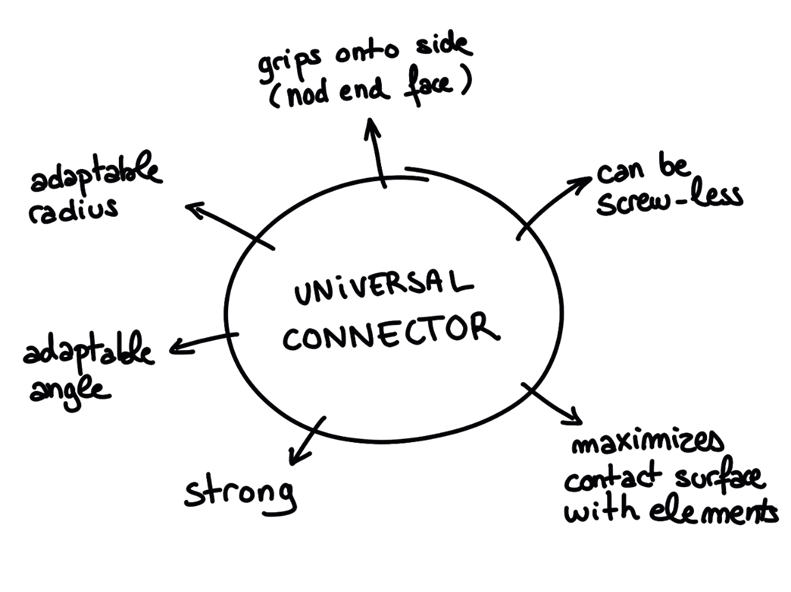

Needs:

Synthesis:

Inspiration :

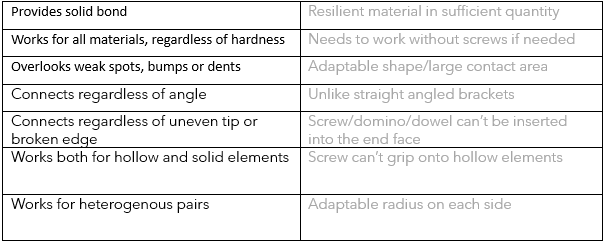

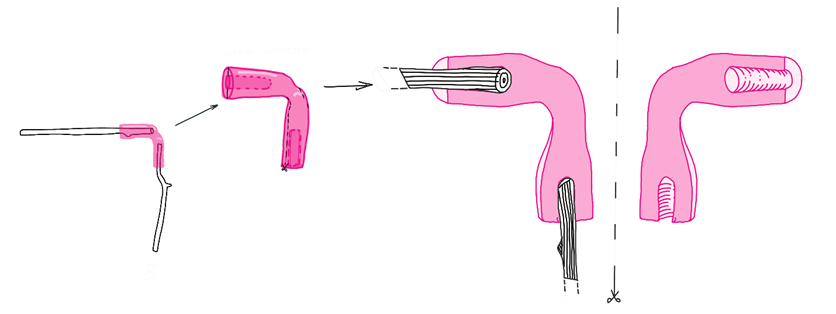

PVC and metal piping is a great example of a connector system which can be screw-less, sturdy, and works for both solid and hollow components.

- Adaptable pipe-like connectors

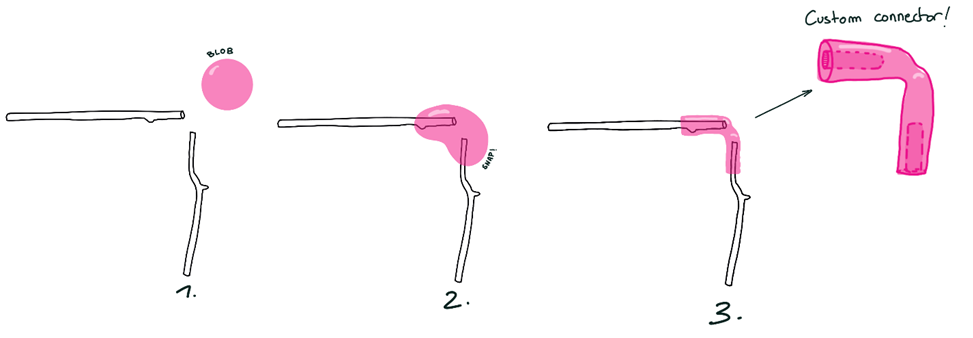

The base idea for the project is custom-made elbow piece which grips onto the end of each beam, and follows its topography

Program 1

(I wish it were as easy as the previous sketch, but allas…)

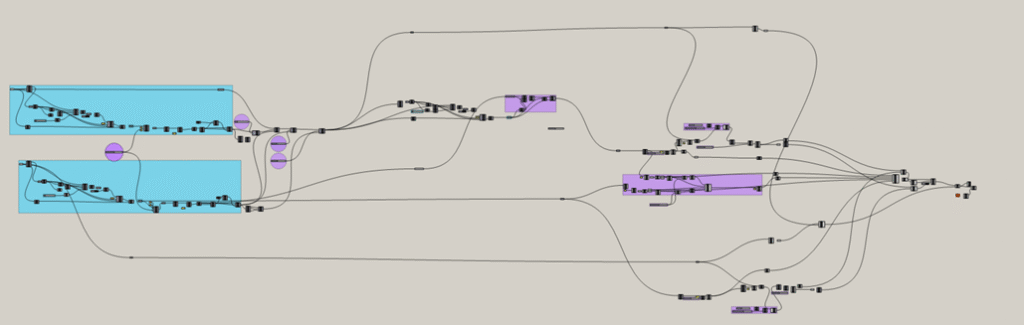

(program 1 overview)

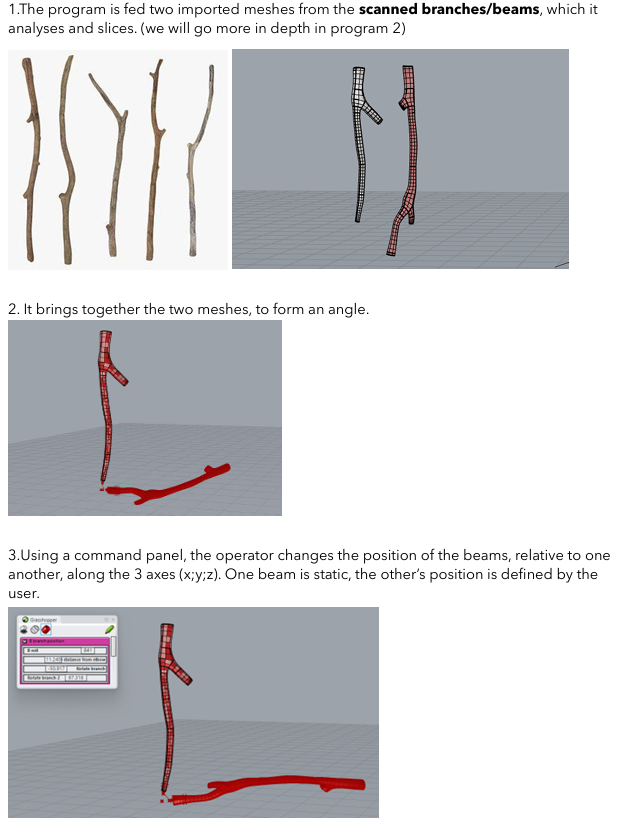

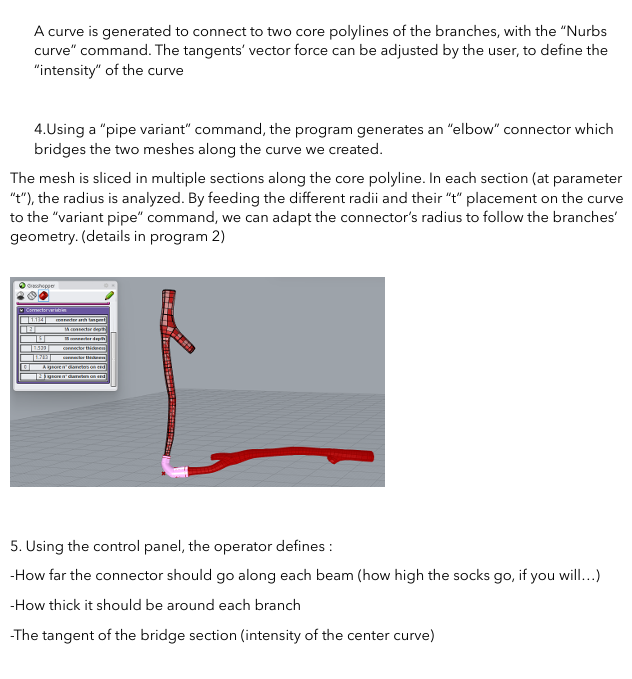

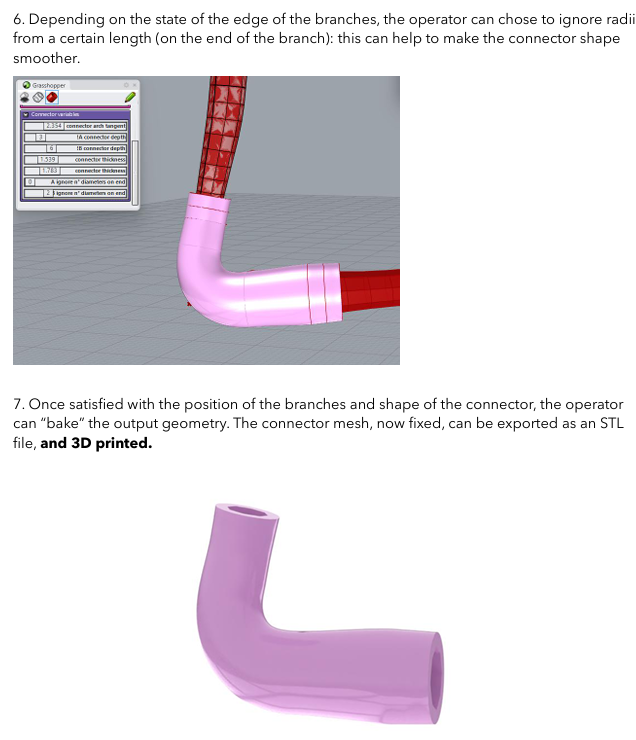

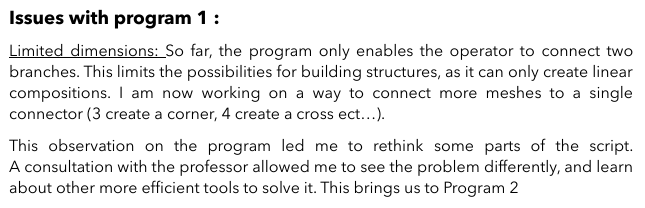

Program use example:

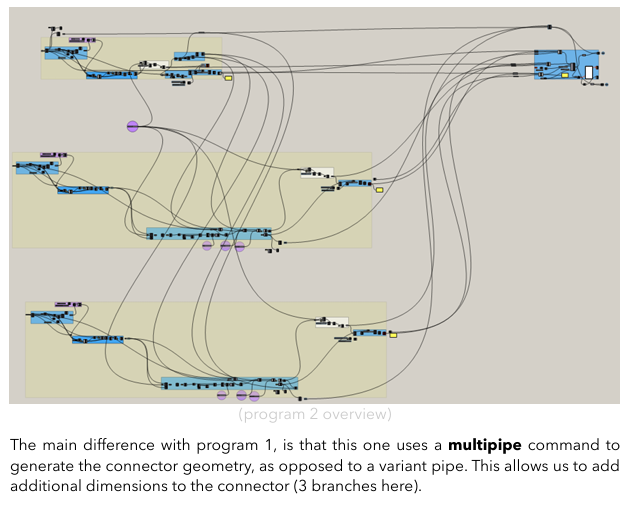

Program 2

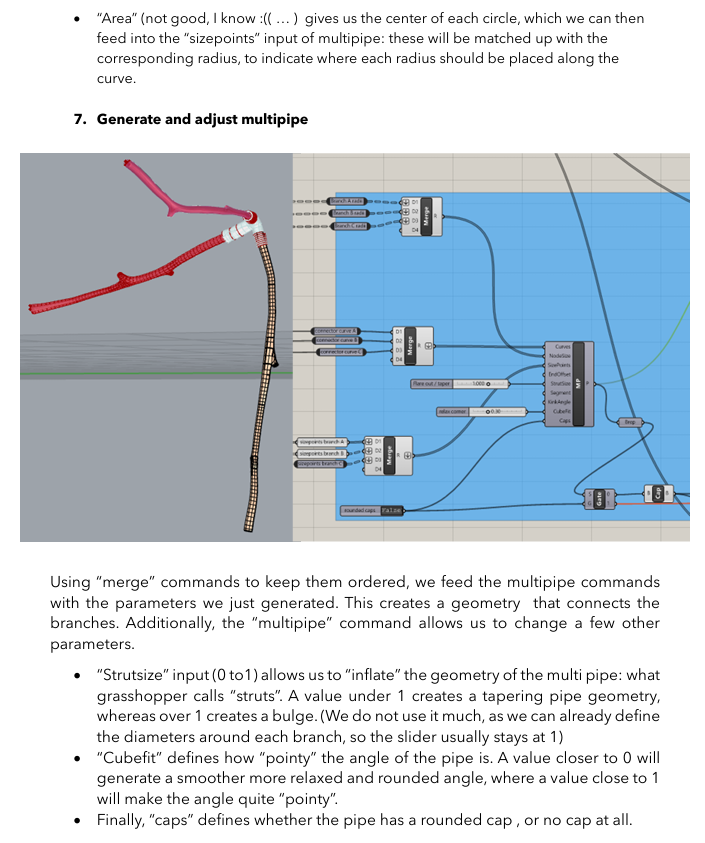

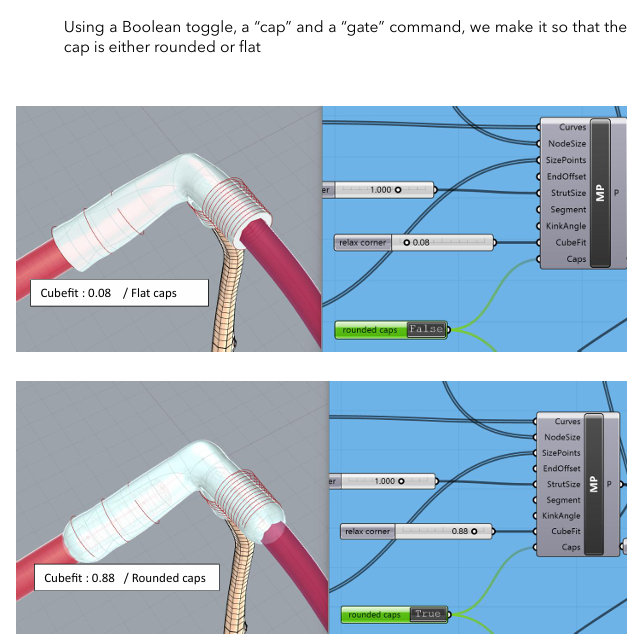

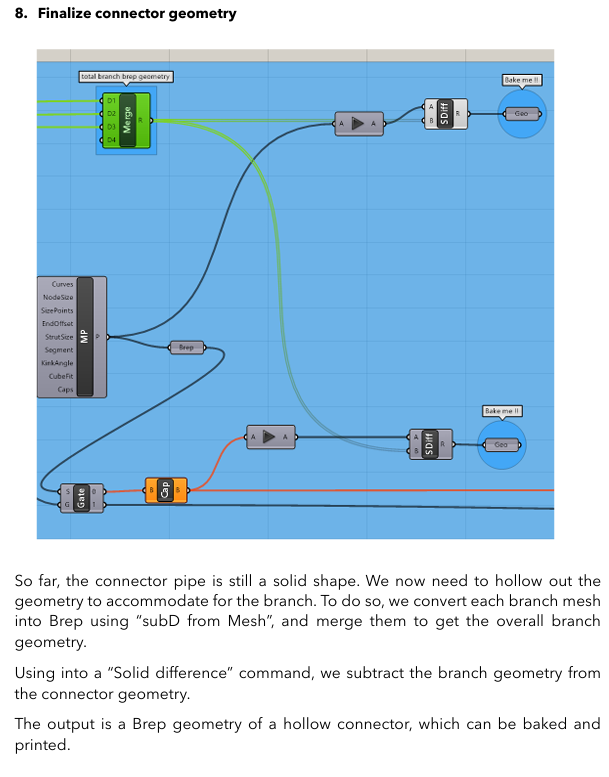

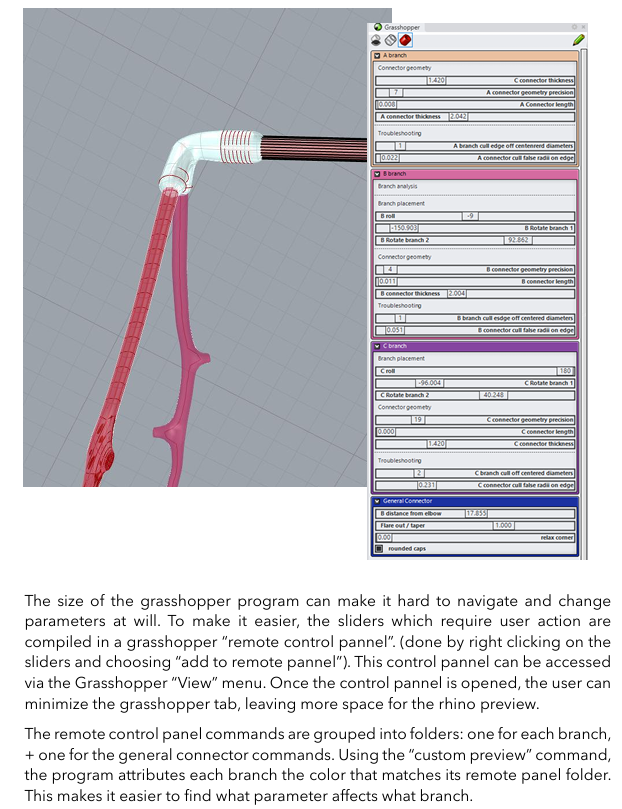

9. User interface

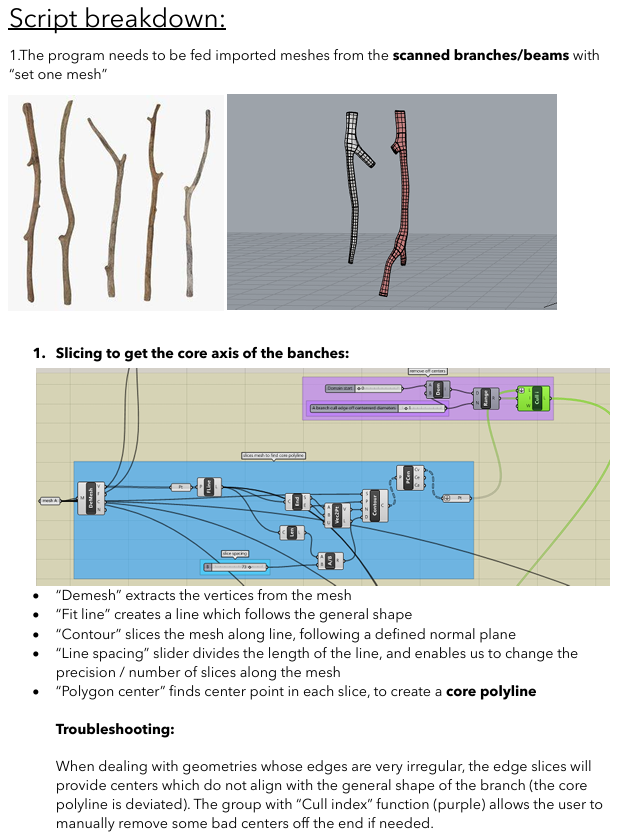

Program use example:

Possible improvements and continuations:

Multiple connections: The program generates one connection at a time. Which means that for now, the operator needs to bake the geometry for each connector, before adding another piece to the structure. In the future, I would like to take the time to improve the program, to have it generate multiple connectors at once. This way, the user could generate and simulate more complex structures.

Slicing and attachment: As of right now, the connector is rendered in a single piece. However, in cases where the beam or branch has a broader end, the connector cannot slide onto the geometry. In order to put the connector on, the user must slice it in two parts and assemble it around the branch. Thus, it would be helpful to develop a section of the script dedicated to slicing the connector geometry. Additionally, the center flat plane would enable easier printing, as it would suppress the need for printing supports.

Personal note:

This challenge has encouraged me to reflect on a topic I wouldn’t have explored otherwise. I rarely use 3D printing in projects and am very glad that I got to explore the possibilities it offers, as well as the problems it should/could be used for.

I have truly enjoyed working on this project and will absolutely try to improve it and use it in the future.

Difficulties :

I felt inspired by the challenge, the idea and first draft came quite quickly. The development of the solution and program, however, turned out to be a bit more challenging than I anticipated.

I was faced with unexpected difficulties when using the grasshopper program, especially the “variant pipe” command. For this, I used resources (tutorials, forums) that were available on the internet. Most importantly, I benefitted from the help of the professor– Simon Prokop, as well as fellow students. This turned out to be extremely

helpful in getting past scripting blocks.